Several key industries experience significant disruptions due to factory closures and reduced shipping capacity during CNY. The following sectors are typically the most impacted:

- Automotive: Raw material, parts shipments and vehicle production suffer due to factory shutdowns.

- Electronics: Component shortages and delays in production of finished products.

- Textiles and Apparel: Disruptions in the manufacturing and shipping of garments and accessories.

- Toys: Delays in toy manufacturing and distribution.

These industries must prepare for delays in manufacturing and shipping as the CNY approaches. Production halts in factories and reduced workforce availability cause order fulfillment to slow significantly.

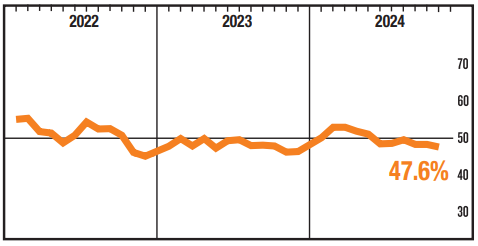

Inventory levels domestically appear to remain low as shippers have not been ramping up ahead of the Chinese New Year (CNY) yet. The ISM's Imports Index for November recorded a reading of 47.6%, showing a continued contraction, which is actually a slight acceleration from October’s 48.3%. This decline suggests that imports are still cooling, and many businesses are not proactively restocking or building up inventory levels in preparation for the post-CNY surge.

This situation could lead to significant capacity constraints in the logistics and supply chain sectors once CNY concludes. As factories in China slowly resume operations, shippers will likely scramble to meet increased demand by replenishing inventory all at once. This rush could cause a bottleneck in the supply chain, as businesses seek to beef up stock levels to make up for the slowdown during the holiday period.

Additionally, businesses that rely on parts from overseas to run their own production could face difficulties. Since many manufacturers and suppliers operate with a just-in-time inventory model, any disruption in parts availability during or after CNY will force them to either scramble for limited resources or delay production, further tightening capacity. The combination of delayed production, heightened demand, and the concurrent need to replenish inventory could strain shipping and transportation networks, leading to delays, congestion, and even increased costs across the board.