Linear Feet LTL Contracts

Shipment Density & Freight Class

Carriers rely on cubic and linear feet measurements to assess the freight class, establish pricing, and manage capacity allocation for shipping services.

To grasp cubic and linear feet concepts, it's essential to discern their distinctions. Logistically, a linear foot equates to 12 inches and quantifies the freight's space along one dimension, typically length. Conversely, cubic feet consider the space occupied by freight across all three dimensions: length, height, and width.

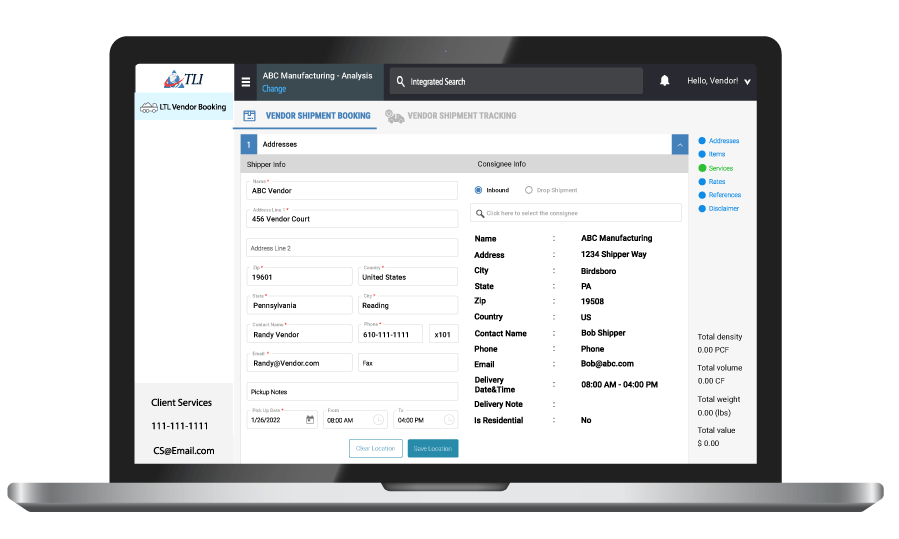

Automated LTL Shipping Software

Understanding Linear Feet

LTL carriers extensively employ cubic and linear footage measurements to assess the density of shipments. This density is crucial for determining the accurate NMFC code, as outlined by the National Motor Freight Association.

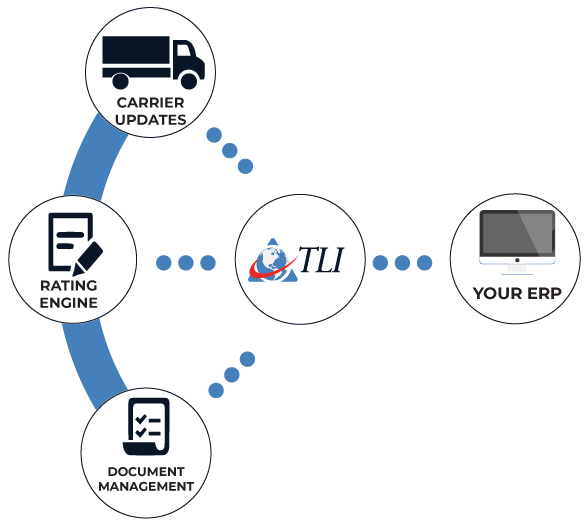

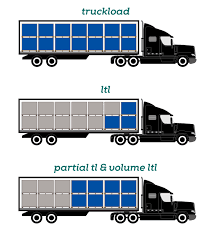

One of the key distinctions between Less-Than-Truckload (LTL) and Full Truckload (FTL) Carriers lies in the volume of freight they can transport in a single shipment. Shippers often make the mistake of loading 7-8 pallets onto an LTL trailer without considering the implications, assuming it's not a full truckload. However, this assumption is costly.

Ultimately, cubic and linear footage requirements dictate the timing, method, and cost of freight shipments. Although specific criteria may vary among carriers, the transportation industry standard for LTL shipping typically stands at 12 linear feet and 750 cubic feet. Shipments exceeding these dimensions necessitate, partial multi-stop truckloads, or FTL carriers with trailers ranging from 48 to 53 feet in length.

LTL Carriers typically set pricing based on freight that adheres to their specific operational guidelines. This often involves limiting a single shipment to occupying 12 Linear Feet of trailer space or less, although some carriers may allow up to 15 feet, and a few even permit 20-24 feet. TLI successfully can provide custom linear foot LTL contracts for shippers with excess coverage if your unique shipper profile warrants this. Calculating cubic feet and density for a shipment can be achieved through a straightforward equation.

PCF Calculation

- Ascertain the height, width, and depth of the shipment in inches, encompassing all packaging such as skids. Multiply these three dimensions to obtain the total cubic inches of the shipment. For multiple pieces, calculate the height × width × depth for each piece separately.

- Divide the total cubic inches by 1,728, representing the number of cubic inches in a cubic foot. This yields the cubic feet of the shipment.

- Divide the weight of the shipment (in pounds) by the total cubic feet. The resulting value represents the pounds per cubic foot, indicating the density of the shipment.

CUBIC CAPACITY CHARGES

What happens when you provide 7 standard 48”x40” pallets to an LTL Carrier that restricts standard rates to 12 Linear Feet or less? In this case, you've loaded 16 Linear Feet of freight onto a trailer with a 12 linear feet limit. This violates the carrier's single shipment rule for Linear Feet, allowing them to apply a different rating structure per their General Rules Tariff. Consequently, established discounts no longer apply, and LTL Carriers may penalize the shipment with cubic capacity charges or volume rates, depending on the circumstances.

LINEAR FOOT RULE

The linear foot rule is a standard in the transportation industry, indicating that shipments occupying 10 linear feet or more of trailer space are charged based on a rate of 1000 lbs per linear foot. Understanding this rule is crucial for shippers managing LTL freight operations. Exceeding a carrier’s linear foot rule can lead to substantial accessorial fees, elevated rates, and potentially a reclassification of the freight as a full truckload.

In many carrier contracts, it's explicitly stated that the carrier bears no responsibility for how the freight is loaded on the trailer, with customers liable for any "over cube" charges. Avoiding these costly errors can be achieved simply by strategizing to minimize the linear footage occupied by a shipment.

To comply with the linear foot rule, shippers should consider deploying TLI's TMS software, and employing loading techniques such as pinwheeling (rotating pallets 90 degrees to fit two pallets side by side in the truck) and double stacking pallets. These methods reduce the trailer space required for a load, enabling shippers to utilize the more economical less-than-truckload shipping transportation mode rather than tendering a full truckload.

Cube Rule

Cubic Feet Space Efficiency

Carriers often price shipments based on cubic feet due to the disproportionate space lightweight items occupy. Products like bubble wrap and foam, with their low density, contribute to this issue. LTL carriers adjust shipment weights to a minimum of 6 pounds per cubic foot for fair pricing. Subsequently, shipments are classified and priced accordingly, typically with NMFC commodity classes of 125 or 150.

Shipping Mistakes

Take control of your freight.

Shippers often mistakenly calculate product dimensions based solely on individual units, overlooking the additional dimensions and weight of pallets & packaging. This oversight can result in costly LTL accessorial charges. Accurate measurement of each pallet is crucial to avoid these expenses. Effective communication of freight dimensions to carriers on the Bill of Lading is critical.